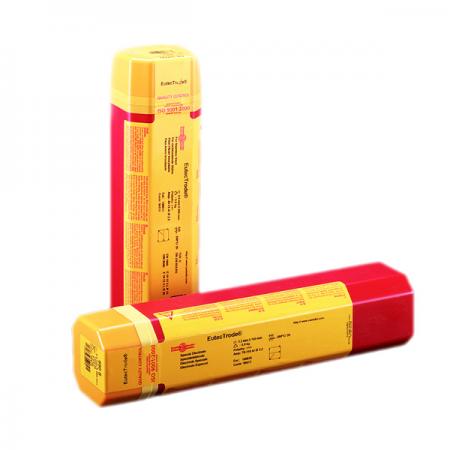

EutecTrode 2-26 D welding electrodes

HOT WELDING OF GREY CAST IRONS

The MMA electrode EutecTrode 2-26 D for cast iron hot welding has been specially adapted to the needs and requirements of wind turbine components. The main objective was to achieve a notch bar impact value of > 10 joules at -20 ° C. The ideal matching of the flux coating formulation around the core rod ensures this requirement. This has been verified in studies by an independent testing laboratory. For cast iron hot welding, the complete component must be slowly preheated to 550 °C to 700 °C, once the weld zone has been suitably prepared. After welding, the post-weld heat treatment is performed depending on the base material. The hot welding of cast iron is always recommended if mechanical properties, machinability and colour of the weld metal must reasonably match those of the cast iron workpiece. Also recommended when distortion, deformation or surface oxidation are justifiable up to certain tolerances.

Applications

- Turbine housing

- Engine – and gearbox housing

- Valve housing

- Rotor housing, etc

Technical Data

Weld metal (untreated)

Values determined for pure weld metal

Yield point Rp0,2

~ 325 MPa

Tensile strength Rm

~ 435 MPa

Elongation A5

~ 12%

Notch impact value -20 °C

> 10 J

Diameter

4 and 6 mm

Categories : Castolin Eutectic, Welding, Welding Electrodes

You Might also Love

Related Products

-

EutecTrode XHD 2230 welding electrodes

-

EutecTrode XHD 6817 welding electrodes

-

TeroMatec® 4923 welding wire

-

TeroMatec® 4660 welding wire

-

TeroMatec® 3220 welding wire

-

EutecTrode XHD 6080 welding electrodes

-

TeroMatec® 4395N welding wire

-

EutecTrode Xuper 6055 welding electrodes

-

EutecTrode XHD 2220 welding electrodes

-

TeroMatec® 4601 welding wire

-

TeroMatec® 4415 welding wire

-

EutecTrode XHD 6868 welding electrodes

-

EutecTrode XHD 6899 welding electrodes

-

TeroMatec® 3952 welding wire

-

TeroMatec® 3302 welding wire

-

EutecTrode XHD 6865 welding electrodes

-

EutecTrode XHD 6860 welding electrodes

-

TeroMatec® 4625 welding wire

-

TeroMatec® 3205 welding wire

-

TeroMatec® 4630 welding wire